2 0 1 7 - 1 1 - 1 8

[Tool]¶

Paint Station¶

After the first few days, I heard an ominous creaking sometimes when I moved the fully loaded station - which made me doubt the power of the glue...

So I decided to add some nails to strenghten the integrity of the station. To prevent the MDF from splintering when hammering in the nails, I first drilled holes with a slighlty smaller diameter than the nail.

Now there are no more ominous sounds no more :-)

Published 2017-11-18 09:42:02

All posts for this project: newest first | oldest first.

2 0 1 7 - 1 1 - 1 5

[Tool]¶

Paint Station¶

The paint station I am currently using I build myself some time ago. It includes a build in wet palette, two cup holders (one for non-metallic, one for metallic) and is A4 size.

It served me well so far, but when moving it around, the paints and brushes always were seperate.

This I wanted to change.

After some Googleing I got myself a new paint station from HobbyZone, which arrived today and was quickly assembled.

I made two slight modifications to it, one was to glue felt pads underneath, the other was to drill two small holes which hold paper clips (which I use to un-clog dropper bottles) which fell through all the stock holes.

Ready for action.

Published 2017-11-15 11:01:07

All posts for this project: newest first | oldest first.

2 0 1 6 - 0 6 - 2 1

[Tools]¶

Static Grass Applicator¶

After reading several blog posts and looking at several YouTube videos, I decided to have a go at my own static grass applicator. I wanted to have something like the Gras-Master 2.0 for quite some time, but for 150,00 EUR - no thanks.

If you want to follow the steps I outline here take care. You are tinkering with electricity and should know what you do. I am not liable for anything.

Following the tutorials I found, I bought:

- an electric fly swat from Amazon - delivered to my door for free with Prime for EUR 9.89.

- Two metal sieves from the Doll... Euro-Store for ... guess what... EUR 1.00.

- 1 meter of cable for EUR 1.50. The local DIY store did not have one-braided cables, so I bought the cheapest 2 braided one.

I used the following tools:

- Clippers

- Screwdriver

- Saw

- Three finger pliers

- Duct tape

I removed the screws and opened the fly swatter (making sure no batteries were in). The yellow top end was easily taken out, but the two yellow halves I needed to break apart. Only the part that is in the handle came easily apart.

The inner electronics - which I did not touch.

I had to press the wire handle a bit tighter with pliers, and carve away some of the yellow rim (bottom of the picture), then the sieve fit perfectly. I pressed it into the yellow part, the tension of the metal grip keeping it firmly in place.

To connect the sieve to the power source, I cut down the wire that ran into the swatter, and with the help of a three finger plier bent the wire and the sieve handle so the wire nestled to the handle form and both fit into the plastic casing.

I cut one end of the black cable, then ripped it apart from there to free the two strands inside.

The copper of the blue wire was then made bare on one end, the second wire from the fly swatter cut off; the two of them then twisted around each other, then fixed and isolated with duct tape. The other wire and the sieve handle were taped together as well.

The other end of the blue wire was attached to an offcut of the wire that ran around the inside of the swatter part, then duct taped as well.

The finished static grass applicator, screwed back together.

First test application of grass on a piece of cardboard. The areas where the grass is lying flat, there was no glue; the parts where the grass is standing upright, there was glue the end of the blue wire was stuck into.

With the loose grass shaken off:

All in all the conversion took me less than an hour and less than EUR 12.00 (deducting the spare sieve, wire from the total purchase). It works quite well and I am sure this little tool will be very helpful for my further carerr as miniature gardener.

Published 2016-06-21 10:45:57

2 0 1 6 - 0 5 - 2 1

[Tools]¶

Plaster Vibrator¶

I ordered some new molds from Hirst Arts. As the castings for my Frag board surly, albeit unfortunately very slowly, are depleting my plaster supply, I ordered a new bag of plaster. The current 25kg bag lasted for about 4 years, the new one hopefully will last as long.

While shopping for the plaster, my eyes were again catched by a vibrating casting machine, that helps removing and/or preventing air bubbles in the casts. I wanted to have such a machine for quite some time, using a pounding board so far.

As I plan to do quite some castings in the near future, I finally invested in the SILFRADENT VIB15.

Published 2016-05-21 10:09:05

2 0 1 5 - 1 1 - 1 5

[Tools]¶

Figure holder¶

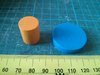

With all the metal bases I use recently, I thought of an easy way to hold my models while painting, when I saw on several places on the nets fellow painters drilling pins into the feet of their models and sticking them on cork cones. This way neither the model nor the base is touched during the whole painting process.

With the metal bases, I do not need pins, but jsut something magnetic. So I build the following devices. I ordered wooden discs and rods from Spielematerial.de, 1cm magnets from MagnetShop.net and screws from the local DIY.

First I drilled a small hole through the center of the disc to guide the screw. The center I found by drawing to random lines across the disc, then a vertical from their exact center. The intersection showed the center of the disc. On side I drilled a hole some mm deep to the screw head into.

On the rods the diameter was too small to use the same method to get the center, so I build a small helper tool - which was not that precise as it turned out later :-(

Here are the rods screwed to the discs:

The final step was to drill a 10mm hole...

... and glue the magnets into place.

Published 2015-11-15 02:37:52

2 0 1 4 - 0 7 - 2 0

[Airbrush]¶

Figure holder device¶

When airbrushing (especially base coating) my models, this is usually done in two steps.

- Take the miniature by the base and airbrush from the waist to the head. Let dry.

- Take the miniature by the head and airbrush from the waist down to the base.

So I need to touch every mini twice, and my hand usually is also black (or grey, or whatever) afterwards.

With my current 15mm WWII project, I have quite a lot of miniatures to base coat, so I thought of a better solution. Here is my clever contraption:

I bought a square wooden rod, some screws, and two metallic plates (whatever the technical term might be) as well as a couple of different sized magnets. I cut the rod to have 14cm either side of the 14cm wide plate, rounded the edges outside the width of the plate first with a rasp, then with two different grains of sanding paper, and screwed the plate in place.

Now I can place magnets on the plate fitting the size of washer a miniature is based on, grip the device on the sides and spray the miniatures without getting paint on my hands. I can also turn the miniature every which way to reach every undercut with the airbrush.

Published 2014-07-20 22:35:00

2 0 1 3 - 0 5 - 1 2

[Tools]¶

Colour Bottle Storage System Extension¶

Having added to my collection of colours in the last few months (one of the reasons is my Christmas present, an airbrush), my storage system did not provide enough space any more. This afternoon I added a fourth box.

I am using the boxes paper packages are delivered in, cut down to 8cm height. Inside, I created a system of compartments, where I put the bottles upside down (to be able to see the colour).

Here are my colours (except those I am currently using in projects):

Published 2013-05-12 21:04:00